INC.

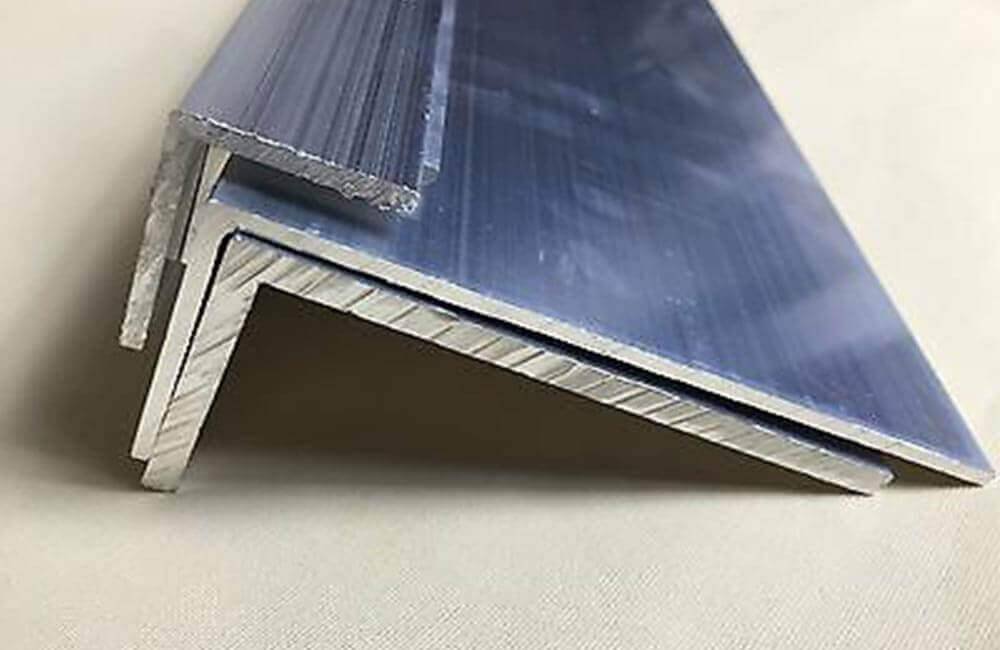

Aluminium 7075 Channels are manufactured from Aluminium Alloy 7075, a high-strength aluminium–zinc alloy renowned for its exceptional mechanical strength, fatigue resistance, and toughness. Alloy 7075 contains significant amounts of zinc, magnesium, and copper, giving it one of the highest strength-to-weight ratios among aluminium alloys. These channels are particularly suited for applications where high load-bearing capacity, structural integrity, and performance under stress are critical. Aluminium 7075 channels offer excellent machinability and can be precisely milled, drilled, turned, and fabricated to tight tolerances, making them ideal for precision engineering applications. Although its corrosion resistance is lower compared to 5xxx and 6xxx series alloys, it can be significantly enhanced through surface treatments such as anodizing, cladding, or protective coatings. Alloy 7075 channels are commonly supplied in T6, T651, and T7351 tempers, ensuring consistent mechanical properties, high strength, and reliable performance in demanding environments. Applications of Aluminium 7075 channels include aerospace structural components, aircraft fittings, automotive performance parts, defence equipment, high-stress mechanical assemblies, tooling plates, jigs and fixtures, and industrial machinery where maximum strength and durability are required. Their ability to withstand high loads while maintaining dimensional stability makes them ideal for critical structural and engineering applications. We supply Aluminium 7075 channels in custom sizes, lengths, thicknesses, tempers, and surface finishes as per client specifications, ensuring precise dimensional tolerances, consistent quality, and full compliance with international standards for aerospace, automotive, defence, and high-performance engineering channel applications.

| European Standard | BS (OLD) | USA (AA) | Germany (DIN) | ISO | IS | Canadian |

|---|---|---|---|---|---|---|

| EN AW-7075 | — | 7075 | AlZn5.5MgCu (DIN 3.4365) | AlZnMgCu1.5 | IS 733 – 7075 | 7075 |

| Alloy | Fe | Si | Mg | Mn | Cu | Zn | Ti | Cr | Each | Al |

|---|---|---|---|---|---|---|---|---|---|---|

| 7075 (min) | — | — | 2.10 | — | 1.20 | 5.10 | — | 0.18 | — | remainder |

| 7075 (max) | 0.50 | 0.40 | 2.90 | 0.30 | 2.00 | 6.10 | 0.20 | 0.28 | 0.05 | remainder |

| Alloy | Temper | UTS (MPa) | % Elongation | |||

| Min | Max | 0.5 mm – 0.8 mm | 0.81 mm – 1.30 mm | 1.30 mm – above | ||

| 7075 | O | 220 | 280 | 14 | 16 | 18 |

| T6 | 510 | 570 | 6 | 8 | 10 | |

| T651 | 540 | 600 | 5 | 7 | 9 | |

| Properties | Metric |

|---|---|

| Density | 2.81 Mg/m³ |

| Melting Point | 477°C – 635°C |

| Specific Heat (100°C) | 960 J/kg·K |

| 1100 | 2014 | 2017 | 2024 | 3003 |

| 5086 | 5052 | 5754 | 5082 | 5083 |

| 6061 | 6063 | 6082 |

| Aluminium 7075 Channels Exporters: | ||||

|---|---|---|---|---|

| Saudi Arabia | Oman | Kuwait | Netherlands | Iran |

| Bahrain | Qatar | UAE | Africa | China |

| Nigeria | Mexico | Canada | Venezuela | United Kingdom |

| United States | South Africa | Malaysia | Bangladesh | Turkey |

| Singapore | Sri Lanka | Australia | Brazil | Germany |

| France | Italy | South Korea | Poland | Belgium |

| Countries we have exported our products to: | |||||

|---|---|---|---|---|---|

| Bengaluru | Mumbai | Chennai | Hyderabad | Kolkata | Pune |

| New Delhi | Ahmedabad | Jaipur | Surat | Salem | Gandhinagar |

| Bhiwandi | Tiruppur | Sivakasi | Jamnagar | Thiruvananthapuram | Rajahmundry |

| Bhubaneswar | Vijaywada | Firozabad | Bokaro Steel City | Rajkot | Bharuch |

| Panna | Raipur | Cochin | Ludhiana | Panipat | Durgapur |

| Peenya | Pimpri-Chinchwad | Channapatna | Kharagpur | Nashik | Bareilly |

| Varanasi | Haldia | Rourkela | Bangalore | Moradabad | Indore |

| Visakhapatnam | Trivandrum | Pithampur | Dibrugarh | Angul | Gwalior |

| Coimbatore | Kannur | Nagpur | Vadodara | Rudrapur | Noida |

| Agra | Bhagalpur | Jamshedpur | Bhilai | Lucknow | Kanpur |

| Thane | Bhopal | Sri City | Bareilly | Hosdurg | Pithampur |