INC.

Aluminium 5083 Angles are manufactured from Aluminium Alloy 5083, a non-heat-treatable, magnesium-based alloy widely recognized for its exceptional strength, outstanding corrosion resistance, and excellent performance in marine and industrial environments. This alloy offers superior resistance to seawater, chemicals, and harsh atmospheric conditions, making it one of the most preferred marine-grade aluminium alloys for heavy-duty applications. Aluminium 5083 provides high strength combined with good formability and excellent weldability, making it suitable for demanding fabrication processes such as bending, forming, cutting, and machining. Although non-heat-treatable, the alloy delivers stable mechanical properties and excellent fatigue resistance, ensuring reliable performance in structurally critical applications. It is commonly supplied in tempers such as O, H111, H116, and H321 to meet marine and structural requirements. Aluminium 5083 Angles are extensively used in shipbuilding, offshore structures, pressure vessels, storage tanks, transportation equipment, chemical processing plants, and heavy engineering applications. Their high strength-to-weight ratio, smooth surface finish, and long-term corrosion resistance ensure extended service life with minimal maintenance. We supply Aluminium 5083 Angles in custom sizes, lengths, thicknesses, tempers, and surface finishes as per client specifications, ensuring precise dimensional accuracy, consistent quality, and compliance with international standards for marine, industrial, and commercial projects.

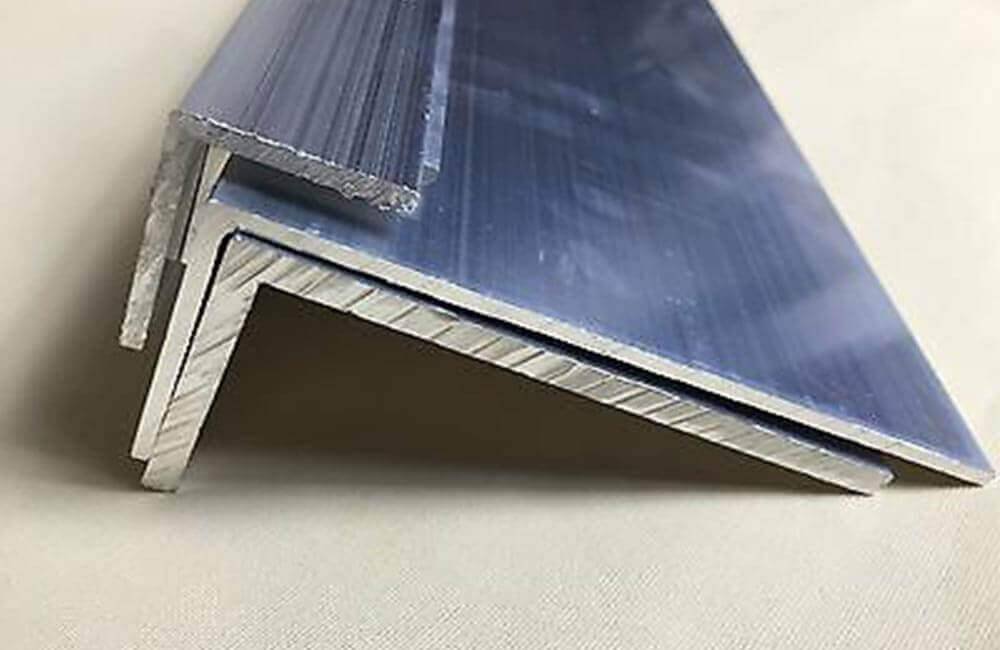

ASME SB211 Aluminium 5083 L Angles, Aluminium Alloy L 5083 Angles, Aluminium Equal L 5083 Angles, Aluminum 5083 L Angles, Aluminium A95083 L Angle Supplier in Mumbai, H111 Temper Aluminum 5083 Unequal L Angles, Aluminium 3.3547 L Angles, ASTM B211 Aluminium 5083 Anodize L Angles Stockist, 5083 Aluminium L Angles Exporter.

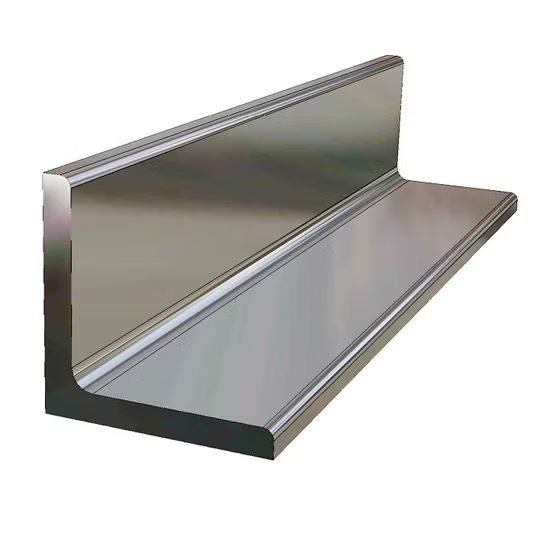

ASME SB211 Aluminium 5083 T Angles, Aluminium Alloy T 5083 Angles, Aluminium Equal T 5083 Angles, Aluminum 5083 T Angles, Aluminium A95083 T Angle Supplier in Mumbai, H116 Temper Aluminum 5083 Unequal T Angles, Aluminium 3.3547 T Angles, ASTM B211 Aluminium 5083 Anodize T Angles Stockist, 5083 Aluminium T Angles Exporter.

| European Standard | OLD | WNr | UNS | ISO | USA (AA) | GERMANY (DIN) |

| AW-AlMg4,5Mn0,7 | AG4,5MC | 3.3547 | A95083 | AlMg4,5Mn0,7 | 5083 | AlMg4,5Mn |

| Al | Si | Fe | Cu | Mn | Cr | Mg | Ti | Zn | Other Each | Others Total |

| Bal | 0.40 max | 0.40 max | 0.10 max | 0.40 / 1.0 | 0.05 / 0.25 | 4.0 / 4.90 | 0.15 max | 0.25 max | 0.05 max | 0.15 max |

| Proof Stress | Tensile Strength | Hardness Brinell | Elongation |

| 125 Min MPa | 275 - 350 MPa | 75 HB | 12 Min % |

| Property | Metric Value |

|---|---|

| Density | 2.66 g/cm³ |

| Melting Point | 570 – 640°C |

| Specific Heat Capacity (at 25°C) | 900 J/kg·K |

| Thermal Conductivity | 121 W/m·K |

| Electrical Resistivity | 0.058 µΩ·m |

| Property | Metric Value |

|---|---|

| Density | 2.66 g/cm³ |

| Melting Point | 605 – 650°C |

| Specific Heat Capacity (at 25°C) | 910 J/kg·K |

| Thermal Conductivity | 130 W/m·K |

| Electrical Resistivity | 0.043 µΩ·m |

| Aluminium 2014 Angles Exporters: | ||||

|---|---|---|---|---|

| Saudi Arabia | Oman | Kuwait | Netherlands | Iran |

| Bahrain | Qatar | UAE | Africa | China |

| Nigeria | Mexico | Canada | Venezuela | United Kingdom |

| United States | South Africa | Malaysia | Bangladesh | Turkey |

| Singapore | Sri Lanka | Australia | Brazil | Germany |

| France | Italy | South Korea | Poland | Belgium |

| Countries we have exported our products to: | |||||

|---|---|---|---|---|---|

| Bengaluru | Mumbai | Chennai | Hyderabad | Kolkata | Pune |

| New Delhi | Ahmedabad | Jaipur | Surat | Salem | Gandhinagar |

| Bhiwandi | Tiruppur | Sivakasi | Jamnagar | Thiruvananthapuram | Rajahmundry |

| Bhubaneswar | Vijaywada | Firozabad | Bokaro Steel City | Rajkot | Bharuch |

| Panna | Raipur | Cochin | Ludhiana | Panipat | Durgapur |

| Peenya | Pimpri-Chinchwad | Channapatna | Kharagpur | Nashik | Bareilly |

| Varanasi | Haldia | Rourkela | Bangalore | Moradabad | Indore |

| Visakhapatnam | Trivandrum | Pithampur | Dibrugarh | Angul | Gwalior |

| Coimbatore | Kannur | Nagpur | Vadodara | Rudrapur | Noida |

| Agra | Bhagalpur | Jamshedpur | Bhilai | Lucknow | Kanpur |

| Thane | Bhopal | Sri City | Bareilly | Hosdurg | Pithampur |